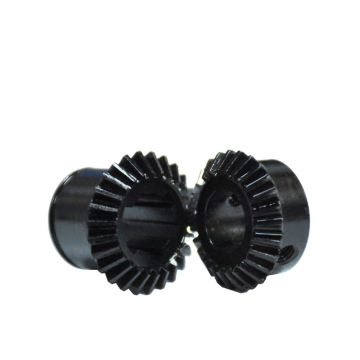

Leading Gear Manufacturing Processing Techniques

Precision gear machining process: forging, normalizing, roughing parts, stock finishing parts, hobbing, chamfering, slotted keyway, deburring, shaving, heat treatment, tooth surface hardening, grinding, quilting, inspection .The principle of precision gear processing: the principle of hobbing, the principle of gear shaping, the original tooth shaper.